TRAINING WELDERS WITH VIRTUAL REALITY

Problem Statement

The current training of welders in Kenya is largely unsafe – owing to occupational health and safety hazards such as eye damage, burns and inhalation of poisonous gases. Secondly, the cost of training is high due to wastage of material, the long training duration, and expenses of raw materials such as gas. To control the cost of training, trainees are usually given up to 3 trials, leaving little room for error. If they are unsuccessful, they are deemed not good enough. Many welders are also good at their craft but are uncertified, hence companies opt to import skilled labour, especially for big projects.

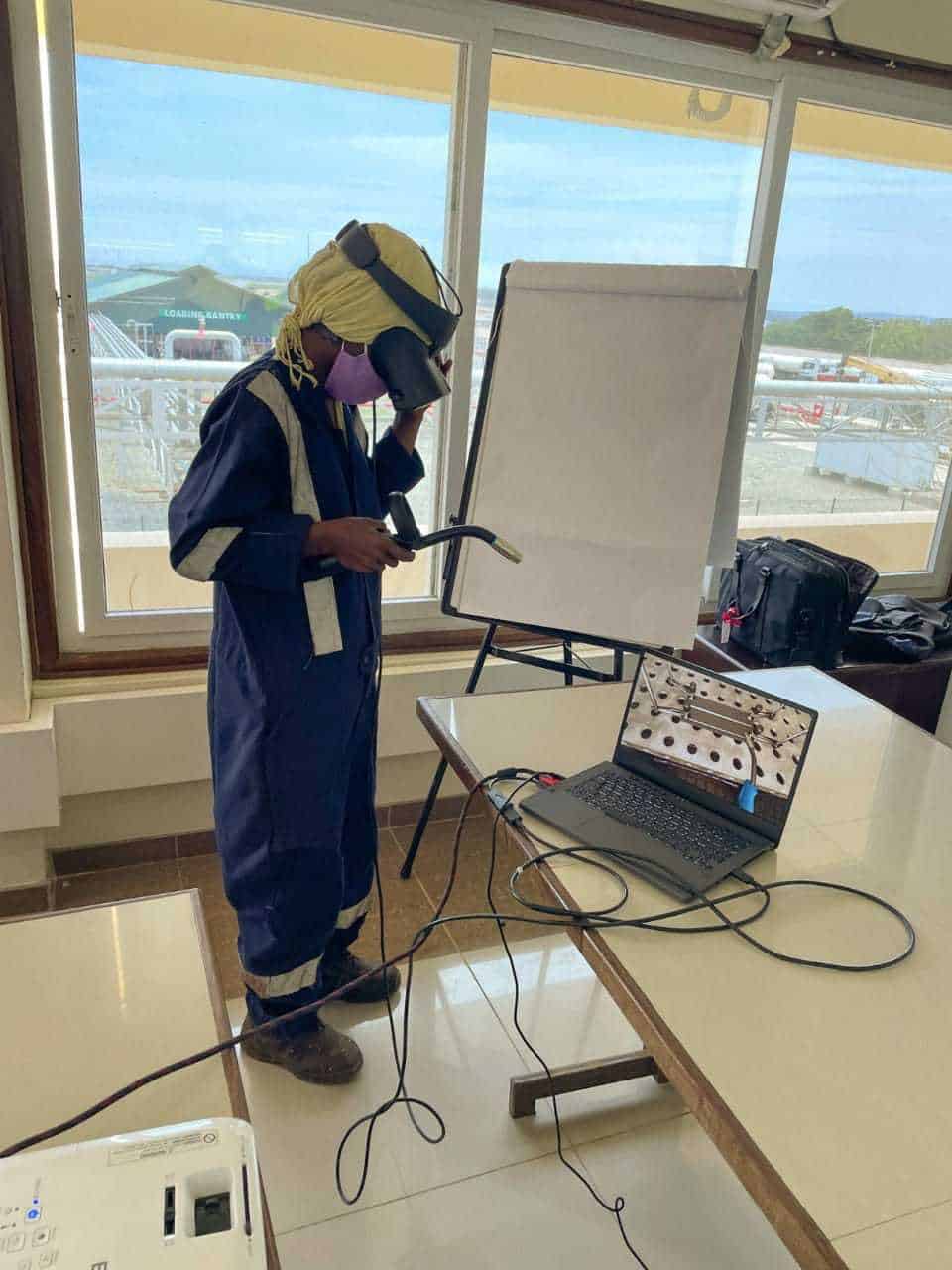

Training with Technology – Our Digital Approach

As a solution, in 2021 The Toolkit for Skills and Innovation Hub started training in welding using VR. This precedent-setting technology in Kenya has lowered the cost of training, eliminated the safety hazards, and reduced the time taken to train as a welder. The Toolkit has observed that once training is done using VR and then trainees later transition to the actual practice, they find it easier to master their craft. Under a model of Recognition of Prior Learning, The Toolkit for Skills and Innovation Hub also proposes to reskill existing welders within 2 months using virtual reality. These welders will then be assessed and certified.

Goal and Description of the Training

The Toolkit for Skills and Innovation Hub is pleased to propose collaboration with partners interested in propelling youth out of poverty through welding, a skill in demand globally. We are flexible on numbers to train, and we also link skilled welders to jobs with our large network of industry players. The Toolkit for Skills and Innovation Hub provides end-to-end solutions from youth mobilization, training, certification, and linkage to jobs.